Introduction to Fiber Splice Cassettes

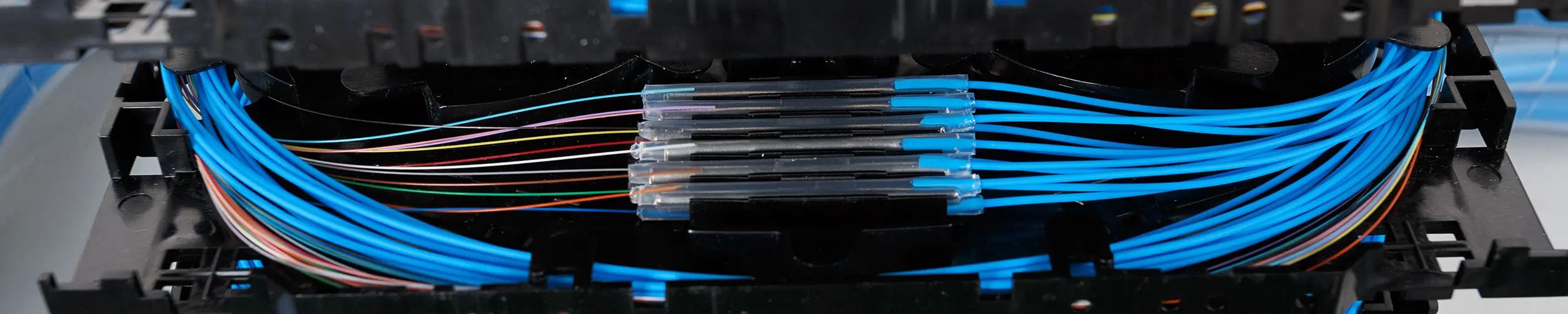

Fiber splice cassettes are integral components within fiber optic networks, designed to enhance the efficiency and reliability of optical fiber splicing. They serve as protective housings that organize and manage the physical connections of optical fibers, ensuring minimal signal loss and optimal performance. The primary purpose of a fiber splice cassette is to facilitate the splicing process by securely holding the spliced fibers and providing a structured environment for the connections.

Splicing is crucial in creating continuous optical paths in fiber optic communication systems. By joining two different fiber strands, such as those that may originate from differing geographic locations or network segments, splicing maintains the integrity and continuity of the light signal. Utilizing splice cassettes streamlines this complex task, offering a systematic approach to managing fiber strains, bends, and connections.

The design of fiber splice cassettes typically includes features that enable effective fiber organization and robust protection against environmental factors. They often incorporate fiber routing and management mechanisms, which assist technicians in maintaining the proper bend radius and avoiding excessive stress on the fibers. Furthermore, the cassettes are usually implemented within larger enclosures or patch panels, contributing to the overall stability of fiber optic networks.

As industries increasingly rely on high-speed data transmission, the importance of reliable splicing and organization within fiber optic systems cannot be overstated. Fiber splice cassettes ensure that connections meet industry standards and enhance the ease of installation and maintenance. Consequently, understanding the function and importance of splice cassettes is essential for professionals operating in fiber optics.

Components of a Fiber Splice Cassette

A fiber splice cassette is a critical component in fiber optic networks, designed to manage fiber splicing operations efficiently. Understanding the various components of a fiber splice cassette is essential for anyone involved in fiber optics. The main components include the base, splice trays, splice holders, and protective cover, each of which plays a vital role in the cassette’s overall functionality.

The base of a fiber splice cassette serves as the structural foundation that houses all other components. Typically made from durable materials, the base is engineered to withstand environmental conditions while providing stability during installation and maintenance. This sturdy framework ensures that all subsequent components are secured and aligned properly, minimizing the risk of fiber damage.

Splice trays are another integral part of the fiber splice cassette. These trays are designed to hold and organize the individual fibers during splicing. Each tray can accommodate multiple fibers, allowing technicians to manage numerous connections seamlessly. The trays are strategically designed to maintain the fibers’ curvature, reducing stress and allowing them to perform optimally.

Within the splice trays, splice holders maintain fibers in position during the splicing process. These holders secure the fibers and ensure precise alignment, which is essential for creating a reliable optical connection. The splice holders also help reduce potential micro bending, which can adversely affect signal integrity.

Finally, the protective cover of the fiber splice cassette is crucial in safeguarding the fibers from external elements such as dust and moisture. The cover also provides additional structural support, ensuring all components remain intact and functioning. By working together, the components of a fiber splice cassette facilitate effective splicing, which is essential for maintaining high-quality connections in fiber optic networks.

Types of Fiber Splice Cassettes

Fiber splice cassettes are essential components in optical fiber networks, protecting and managing splices between fiber strands. Various fiber splice cassettes exist, each tailored to specific applications and requirements. Understanding these types can help you select the most suitable option for a particular project.

One way to categorize fiber splice cassettes is by their functionality. Standard cassettes accommodate a fixed number of splices, and advanced cassettes allow for greater flexibility and modular configurations. Modular splice cassettes enable users to expand or reduce capacity without replacing the entire system. This flexibility is particularly beneficial in environments where network demands may change over time.

Another critical distinction among splice cassettes is compatibility with different fiber types. Some cassettes are designed for single-mode fibers, while others work with multimode fibers. Selecting the right cassette based on fiber type is essential for ensuring optimal performance and maintaining signal integrity. Additionally, hybrid splice cassettes are available, accommodating mixed fiber types to increase versatility in installations.

Fixed vs. modular designs represent another aspect when evaluating splice cassettes. Fixed designs are typically simpler and more cost-effective, ideal for installations with predetermined requirements. Conversely, modular designs can adapt to future changes, making them suitable for dynamic environments that experience variable demands on their networks. Some cassettes also incorporate integrated splice trays or management systems that enhance organization and facilitate easier maintenance.

Moreover, distinguishing features may include environmental ratings, ease of installation, and the number of splices supported. Each aspect contributes to fiber splice cassettes’ overall usability and effectiveness in different applications. Understanding these differences enables engineers and technicians to select appropriate products to efficiently fulfill specific operational needs.

The Role of Fiber Splice Cassettes in Network Infrastructure

Fiber splice cassettes serve a crucial purpose in modern network infrastructure by facilitating the seamless connection of optical fibers. These compact units significantly enhance the performance, reliability, and organization of fiber optic networks in indoor and outdoor applications. Their primary function is to protect and manage the splicing of fiber cables, ensuring that the transmitted signals remain strong and undistorted.

Fiber splice cassettes are typically integrated within fiber distribution frames (FDFs) in indoor environments. These frames provide a structured and efficient way to manage multiple fiber optic connections. By using splice cassettes, technicians can ensure that each fiber strand is securely organized and accessible, which significantly reduces the risk of signal loss and cross-talk between fibers. Properly maintained splice cassettes also allow for easy identification and troubleshooting of connections, which is essential in maintaining optimal network performance.

Outdoor settings pose additional challenges, such as exposure to environmental factors. Fiber splice cassettes designed for outdoor use are built with robust enclosures, protecting the splices from moisture, temperature fluctuations, and physical damage. This environmental protection is vital to sustaining network reliability and minimizing downtime. Moreover, outdoor splice cassettes can integrate with existing equipment, such as splice enclosures and closures, providing a cohesive network solution.

Furthermore, the efficient organization and management enabled by fiber splice cassettes contribute to improved network performance. Users can achieve higher data transmission rates by minimizing attenuation losses, resulting in faster and more reliable communication. Thus, fiber splice cassettes are not just passive components; they are integral to establishing a high-quality fiber optic network that meets the demands of today’s data-intensive environments.

Benefits of Using Fiber Splice Cassettes

Fiber splice cassettes offer many advantages that significantly enhance the efficacy of fiber optic installations. One primary benefit is improved organization. These cassettes serve as a central hub for storing and managing fiber splices, which minimizes clutter and simplifies the intricate nature of fiber installations. Providing a systematic approach to managing multiple fibers, they help technicians easily identify, access, and manage connections, leading to better overall workflow in network deployment and maintenance.

Moreover, the ease of maintenance afforded by fiber splice cassettes cannot be overstated. These cassettes are designed to allow for quick and hassle-free access to the fibers housed within. In case of a fault or need for adjustment, technicians can swiftly locate and troubleshoot issues without dismantling complex cabling systems. This reduces downtime and ensures that network services remain reliable for end-users. Furthermore, regular inspections and necessary splicing can be carried out more efficiently, reducing operational costs.

Another essential benefit of using fiber splice cassettes is their protection of fiber connections. These cassettes shield delicate fibers from physical damage, dust, and environmental factors by encapsulating splices within sturdy frames. This protection is crucial in maintaining the integrity of fiber connections, which are susceptible to interruption if improperly handled. Furthermore, the design of splice cassettes ensures that fibers are aligned correctly during the splicing process, which is vital for minimizing insertion loss and ensuring optimal signal transmission.

In summary, the advantages of implementing fiber splice cassettes include improved organization, streamlined maintenance, enhanced protection for fiber connections, and proper alignment during splicing. These benefits contribute to fiber optic networks’ overall efficiency and reliability, making them an indispensable component of modern telecommunications infrastructure.

Best Practices for Installing Fiber Splice Cassettes

Installing fiber splice cassettes involves carefully planned steps to ensure optimal performance and longevity for fiber optic connections. One of the primary best practices is to handle fibers with utmost care. This involves avoiding excessive bending or twisting of the fibers, as these actions can induce micro-bends that impact signal quality. It is essential to follow the bend radius specifications of the fiber optic cable you are installing to preserve the integrity of the transmission.

Preparation is crucial before proceeding with the actual splice. This includes stripping the fibers accurately to the required length without causing damage. When preparing the splice, it is advisable to use high-quality tools specifically designed for fiber optics. Precision cleaving and the use of the right splice type—whether it be fusion or mechanical—are essential in ensuring minimal splice loss. Additionally, consulting relevant guidelines for specific fiber types may aid in optimizing splice performance.

Another significant aspect of the installation process is maintaining cleanliness. Dust and contaminants can significantly impair the performance of the splice cassettes, leading to increased attenuation and potential failure. It is recommended that fibers and connectors be cleaned with compressed air or lint-free wipes before the installation phase. Moreover, the work area should be kept clean and free from unnecessary materials that could compromise the installation process.

Furthermore, proper alignment during the splice process is vital. Aligning the fibers accurately helps achieve the best possible connection. This alignment should be followed by securely anchoring the connections in place, as the movement of the fibers can introduce additional losses. By adhering to these best practices, technicians can greatly enhance the performance and reliability of fiber splice cassettes, contributing to a robust fiber optic network.

Common Challenges in Using Fiber Splice Cassettes

Fiber splice cassettes serve a pivotal role in the deployment and management of fiber optics networks. However, their effective utilization can be hindered by several common challenges. One prevalent issue is improper splicing, which can arise from a lack of skill, inadequate training, or subpar equipment. When the fibers are not accurately aligned during splicing, it can lead to high signal loss and diminish the network’s overall performance. To mitigate this, it is essential to ensure that technicians undergo proper training and utilize high-quality splicing tools to achieve optimal results.

Environmental factors also pose significant challenges when working with fiber splice cassettes. Factors such as temperature fluctuations, humidity, and exposure to dust can adversely affect the integrity of the connections. For instance, high humidity levels can lead to moisture ingress, which may deteriorate the connectors’ performance. To combat these environmental influences, it is advisable to install splice cassettes in climate-controlled environments whenever possible and incorporate protective measures, such as sealing mechanisms, to prevent moisture intrusion.

Maintenance concerns are another critical aspect to consider when deploying fiber splice cassettes. Neglecting routine maintenance can result in gradual degradation of the splice performance, leading to communication issues over time. Regular tests, inspections, and cleaning ensure fiber adhesive and other components remain in good condition. Implementing a comprehensive maintenance schedule, which includes periodic cleanliness checks, can significantly enhance reliability and extend the lifespan of the spliced connections. By proactively addressing these challenges, fiber optic systems can maintain optimal performance and efficiency.

Choosing the Right Fiber Splice Cassette for Your Needs

Selecting the appropriate fiber splice cassette is crucial for ensuring optimal performance in fiber optic networks. Several factors must be considered, including the type of fibers, capacity needs, installation environment, and compatibility with existing systems, to make an informed decision.

First and foremost, it is essential to determine the type of fibers that will be spliced. Fiber splice cassettes are designed for specific fiber types, such as single-mode or multi-mode fibers. Single-mode fibers require precise alignment and typically demand cassettes that accommodate their smaller core diameter. On the other hand, multi-mode fibers have larger core diameters and may utilize different cassettes that support the decreased precision in alignment. Understanding the inherent characteristics of the fibers used will guide the selection process and ensure optimal connectivity.

Capacity is another critical factor when choosing a fiber splice cassette. The number of fiber strands that need to be organized and managed within the cassette must be assessed. Cassettes come in various capacities, ranging from a few fibers to over a hundred. Opting for a cassette that can accommodate future scalability is also wise, allowing additional fibers to be integrated without replacing existing infrastructure.

The installation environment plays a significant role in determining the suitable cassette. For instance, indoor installations may prioritize compact design, while outdoor settings may require cassettes built to withstand harsh weather conditions. Additionally, compatibility with existing systems is paramount to ensure seamless integration. The selected fiber splice cassette should be compatible with terminations, connectors, and other infrastructure components already in place.

By carefully evaluating these factors, one can effectively choose the right fiber splice cassette to meet their specific needs and ensure a reliable and efficient fiber optic network.

Future Trends in Fiber Splice Cassette Technology

Fiber splice cassette technology is rapidly evolving, driven by the increasing demand for higher data transmission speeds and more efficient networking solutions. One notable trend is the move towards enhanced performance capabilities. Manufacturers are focusing on designing splice cassettes that facilitate increased fiber counts and superior optical performance. Innovations in materials and engineering techniques are enabling the production of splice cassettes that can handle more fibers while minimizing signal loss and effectively managing thermal dynamics.

Furthermore, integrating advanced technologies, such as automated splicing systems, transforms how splice cassettes are utilized in networking environments. Automatic splicing machines paired with smart splice cassettes can streamline installation processes, reduce human error, and ultimately shorten project timelines. This automation trend improves operational efficiency and enhances the usability of splice cassettes in different settings, particularly in high-density data centers.

The growing importance of sustainability is also shaping the development of fiber splice cassettes. Manufacturers increasingly seek eco-friendly materials and production methods, responding to the global push for environmentally responsible technology solutions. This shift addresses environmental concerns and can lead to more durable products that meet the rigorous demands of modern networking applications.

Another critical area of innovation is the modular design of fiber splice cassettes. By adopting a modular approach, these cassettes can be easily customized and upgraded, allowing greater flexibility to accommodate evolving networking requirements. Adapting to modular components becomes essential as organizations scale their operations and seek to future-proof their infrastructures.

In conclusion, the future of fiber splice cassette technology promises significant performance, usability, and sustainability enhancements. As these trends continue to unfold, the role of fiber splice cassettes in high-speed networking and data center applications will undoubtedly become more prominent, paving the way for continued innovation in this vital area of telecommunications.